Applications and development of ceramic cutting tool

Post Date: 08 Apr 2015 Viewed: 1026

High speed cutting is the most effective solution to production efficiency in modern manufacturing processes. With increasing demands for aerospace, auto, weapon as well as processing strength and precision, ceramic cutting tools are widely applied to high speed cutting due to their favorable mechanical properties, longer tool life than other tools with fewer times of switching cutters. Besides, the raw material for ceramic cutting tools is silicon which is abundant on the earth and is environmental friendly during manufacturing. Therefore, it is worth studying the applications of ceramic cutting tools in fields of metal cutting technology and advanced ceramic materials.

1. Types of ceramic cutting tools

Ceramic cutting tools are made of special ceramic powders through high pressure. Alumina series ceramic, silicon nitride ceramic and compound Si3N4-Al2O3 ceramic are the three main patterns.

(1) Al2O3 ceramic cutting tool.

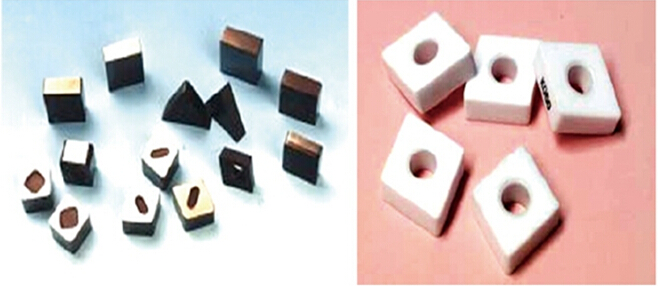

The main ceramic material is Al2O3, which includes pure Al2O3, hybrid Al2O3 added with carbide, oxide, nitride or boride etc., and hybrid Al2O3 added with both compounds and binder metals, as shown in figure 1. Al2O3 ceramic cutting tool is further divided into 5 types: pure Al2O3 ceramic cutting tool, Al2O3-TiC ceramic cutting tool, Al2O3-ZrO2 ceramic cutting tool, Al2O3-SiC whisker reinforced ceramic cutting tool and Al2O3-(W, Ti) C gradient ceramic cutting tool.

(2) Silicon nitride ceramic cutting tool

This type of ceramic has Si3N4 ceramic and Si3N4 based ceramic added with other carbides as shown in figure 2. Silicon nitride series ceramic cutting tool is a kind of hot pressed ceramic with MgO as the additive. The main material is nitrogen and silicon which can replace cemented carbide, saving much metals like W, Co, Ta and Nb etc..

(3) Si3N4 - Al2O3 ceramic cutting tool

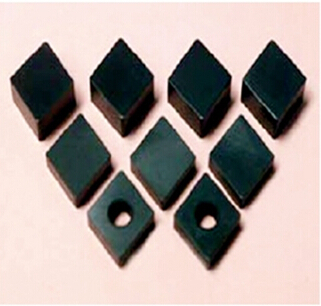

Sialon ceramic cutting tool is made of hybrids of Al2O3, Si3N4 and AlN through hot pressed sintering at high temperature as shown in figure 3. The additive Y2O3 can facilitate densification of the structure. As the coefficients of thermal expansion of TiC and Si3N4 differ greatly, much thermal stress is generated caused by increasing temperature during the high speed cutting process, as a consequence, the tool life decreases. To solve this problem, many countries developed (α′+β′)-Sialon ceramic cutting tool.

2. Selection for ceramic cutting tool

Ceramic cutting tools are mainly used in high speed cutting for plain steel and cast iron that cannot be machined by cemented carbide tools, and for hard machined materials. Different types of cutting tools have the specific machining scope.

(1) Al2O3 based ceramic cutting tools are used to machine hard and brittle metals like chilled cast iron and hardened steel, as well as copper alloy, graphite, engineering plastic and compounds. It performs better than Si3N4 based ceramic in machining steels. It is often used for cutting of machine parts and high-precision cutting.

It is not recommended to use this kind of cutting tool for small parts processing, interrupted cutting for steels and elementary substance like Mg, Ti and Be etc, because diffusion wear, releasing of cutting edges and cutting edge chipping of tools tend to occur. Moreover, the matrix of tools contains Al which tends to reacts with Al parts and Al alloys, leading to diffusion wear and adhesion wear. Therefore, the Al2O3 based ceramic cutting tool is not suitable for Al alloy. Similarly, both Al2O3/TiC and Al2O3/(W,Ti)C contain Al and Ti, and they are also not suitable to process Al alloy and Ti alloy. Particulates or whiskers of SiCw reinforced Al2O3 ceramic cutting tools perform well in processing pure nickel, high nickel alloy and nickel based superalloy; however, when it is used to process steel products at high cutting temperature, SiCw tends to reacts with Fe, thus decreasing strength and wear resistance of the whisker SiCw, weakening binding strength between whisker and matrix and accelerating the tool wear. Therefore, the cutting tools added with SiCw whisker are not suitable to process steel and cast iron.

(2) Si3N4 ceramic cutting tools are used to process cast iron, superalloy and high speed cutting as well as heavy cutting; its lifetime is 10 times longer than cemented carbide tools. Moreover, Si3N4 ceramic is of good self-lubricating performance, low friction coefficient and high adhesion resistance and free of nodular powders; it has sharp edge, resulting in good surface quality of work pieces, and is suitable for turning of materials which tends to have nodular powders such as cast silicon-Al alloy etc., therefore, it is widely used in cylinder block of auto engineer.

The fracture toughness and thermal fracture resistance of Si3N4 ceramic cutting tools exceed that of Al2O3 based ceramic cutting tools, widely used in cutting process of cast iron and nickel based alloy. Abrasive wear occurs when Si3N4 ceramic cutting tools are used in high speed cutting of cast iron while chemical wear occurs when it is used in high speed cutting of carbon steel. Due to that Si3N4 reacts greatly with Fe and reciprocal diffusion between Si and Fe occurs, Si3N4 ceramic cutting tools are not suitable to high speed cutting of pure steel and carbon steel etc but to cast iron and superalloy.

(3) Si3N4- Al2O3 compound ceramic cutting tool like Sialon cutting tool is of high strength and toughness, suitable for high speed cutting of cast iron and nickel based alloy like grey cast iron, chilled cast iron, spheroidal graphite cast iron and wear resistance cast iron of high alloy, not suitable for steel products.

3. Usage of ceramic cutting tools

(1) Machine tools assorting with ceramic tools should be of good rigidity, enough powder and high rotation speed as well as tool holding performance in case of tool failure and cutting edge chipping.

(2) Appropriate types of ceramic materials should accord with particular properties of machined materials.

(3) Negative rake angle (-5', -12') is set for a better exertion of compressive strength of the tool.

(4) For a more efficient exertion of heat resistance and abrasion resistance of the ceramic cutting tools, bigger back engagement and higher cutting speed is recommended with less feed.

(5) Ceramic cutting tools are sensitive to shock and oscillating load and poor rigidity of the system tends to cause cutting edge chipping or shorten the tool lifetime. Therefore, it is suggested that cutting tools are mounted on the universal tool and cutter grinding machine and grinded for a negative rake angle by a diamond grinding wheel to ease shock.

(6) For hard casting with sand marks and voids, a portable grinder is suggested to dress the defects in order to get better processing performance.

4. Summary

Ceramic materials are regarded as the most efficient and promising cutting tool material, the ceramic cutting tool can replace grinding with turning, replace polishing with milling and improve the surface quality of work pieces. With the development of new materials of ceramic cutting tool, high efficient machine tools and high speed cutting technology will make greater achievements with both economical and environmental friendly benefits.